Exploring the Evolving Landscape of Additive Manufacturing Materials Trends

Additive manufacturing, also known as 3D printing, has witnessed a rapid evolution in recent years, driven in part by advancements in materials technology. These innovations play a pivotal role in shaping the future of additive manufacturing, opening up new possibilities and applications across various industries.

**1. Diverse Material Options for Enhanced Functionality

One of the notable trends in additive manufacturing materials involves the diversification of available options. Traditional 3D printing materials like PLA and ABS are being complemented by a growing array of advanced polymers, metals, ceramics, and composites. This expansion allows manufacturers to choose materials tailored to specific applications, enhancing the functionality and performance of printed components.

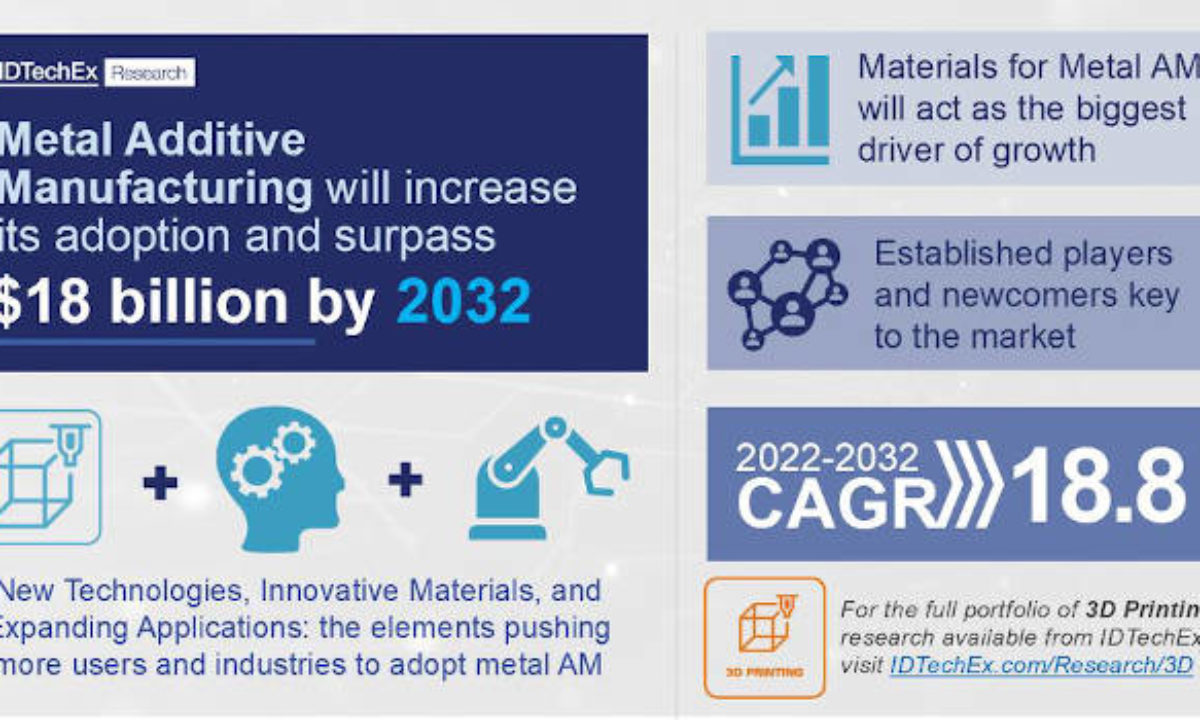

**2. Metal Additive Manufacturing Gains Momentum

Metal additive manufacturing is experiencing a surge in popularity, marked by the increasing adoption of metal 3D printing techniques. From aerospace components to medical implants, the ability to print intricate metal structures with precision is transforming industries. The use of materials like titanium, aluminum, and stainless steel in additive manufacturing opens new frontiers for creating robust and lightweight metal parts.

**3. Biodegradable and Sustainable Materials

With an increasing focus on sustainability, there’s a growing trend towards the development of biodegradable and eco-friendly additive manufacturing materials. Bioplastics and bio-based polymers are emerging as viable alternatives, offering the potential to reduce the environmental impact of 3D printing. This shift towards sustainability aligns with broader efforts in manufacturing to minimize waste and carbon footprint.

**4. Functional and Smart Materials Integration

The incorporation of functional and smart materials is another exciting trend in additive manufacturing. From materials with conductive properties for electronics to those with self-healing capabilities, these innovations expand the possibilities for creating multifunctional 3D-printed objects. Industries such as electronics, healthcare, and consumer goods stand to benefit from these advancements in material science.

**5. Nanomaterials and Enhanced Performance

The utilization of nanomaterials in additive manufacturing is contributing to improved mechanical and thermal properties of printed objects. Nanocomposites, reinforced with nanoparticles, offer enhanced strength, durability, and heat resistance. As researchers delve into the realm of nanotechnology, we can anticipate further breakthroughs in material science, pushing the boundaries of what is achievable with 3D printing.

**6. Customization through Multi-Material Printing

Multi-material 3D printing is gaining traction, enabling the simultaneous use of different materials in a single print job. This capability opens avenues for creating complex, multi-functional objects with varying properties. From flexible joints to rigid structures within the same printed component, customization options are expanding, allowing for greater innovation and efficiency in design.

**7. Focus on Post-Processing Techniques

While the printing process is crucial, the post-processing stage is equally significant. Trends in additive manufacturing materials also encompass advancements in post-processing techniques to refine and enhance printed objects. Techniques such as surface finishing, polishing, and coating contribute to achieving the desired aesthetics, functionality, and performance of 3D-printed components.

Navigating the Future with Additive Manufacturing Materials Trends

As we navigate the ever-evolving landscape of additive manufacturing, staying informed about materials trends is essential. These trends not only impact the capabilities of 3D printing technology but also influence the applications and industries that benefit from it.

To delve deeper into the latest trends in additive manufacturing materials, visit Additive Manufacturing Materials Trends. Explore how material innovations are shaping the future of 3D printing and driving advancements across diverse industries.