Adaptable Excellence: Unveiling the Power of Flexible Manufacturing Cell Design

In the dynamic landscape of modern manufacturing, flexibility is a key determinant of success. Flexible Manufacturing Cell Design stands at the forefront of this shift, offering versatility and efficiency that traditional manufacturing setups may struggle to match.

The Essence of Flexible Manufacturing Cell Design

Versatility in Production:

Flexible Manufacturing Cell Design revolves around creating modular production units capable of adapting to different tasks. These cells integrate various machines and technologies, allowing manufacturers to switch between different products and production processes swiftly.

Key Components and Features

Modularity and Interconnectivity:

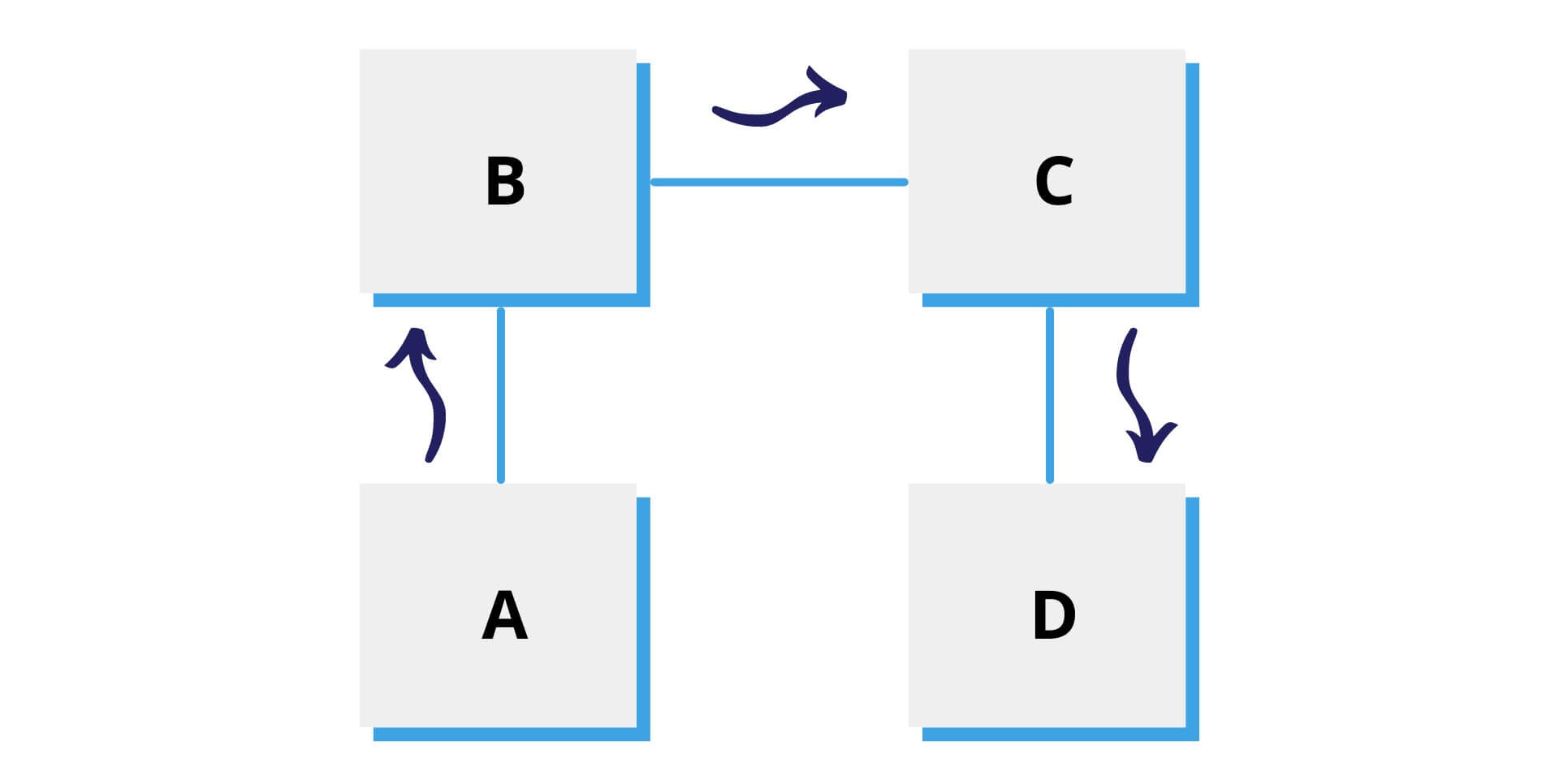

A hallmark of Flexible Manufacturing Cell Design is modularity. Each cell is designed to be a self-contained unit, capable of operating independently or in collaboration with other cells. The interconnectivity of these modules enables seamless communication and coordination.

Automation Integration:

Automation is a linchpin in Flexible Manufacturing Cell Design. The integration of robotics and automated systems enhances the adaptability of the cells. Automated material handling, machine loading, and quality control contribute to a streamlined and efficient manufacturing process.

To learn more about Flexible Manufacturing Cell Design, visit Flexible Manufacturing Cell Design.

Advantages in Modern Manufacturing

Enhanced Efficiency:

The adaptability of Flexible Manufacturing Cells translates into enhanced efficiency. Quick changeovers and the ability to accommodate varying production volumes contribute to reducing downtime and optimizing resource utilization.

Cost-Effectiveness:

While the initial setup cost might be higher, the long-term cost-effectiveness of Flexible Manufacturing Cell Design becomes evident. Reduced labor costs, minimized material wastage, and efficient use of space contribute to overall savings.

Applications Across Industries

Automotive Manufacturing:

In the automotive industry, where product variations are common, Flexible Manufacturing Cell Design shines. Manufacturers can swiftly adjust production lines to accommodate different models, ensuring agility in responding to market demands.

Electronics and Consumer Goods:

The rapidly evolving electronics and consumer goods sectors benefit from Flexible Manufacturing Cells. The ability to adapt to diverse product specifications and handle complex assembly processes aligns with the dynamic nature of these industries.

Challenges and Considerations

Initial Investment and Training:

While the long-term benefits are substantial, the initial investment in Flexible Manufacturing Cell Design can be significant. Additionally, providing adequate training for personnel to operate and maintain these systems is crucial.

System Integration Complexity:

Integrating Flexible Manufacturing Cells into existing production setups can pose challenges. Compatibility issues and the need for seamless communication between different cells require careful planning and execution.

The Future Landscape of Manufacturing

Customization and Small-Batch Production:

As consumer preferences shift towards customization and smaller production runs, the flexibility offered by these manufacturing cells becomes invaluable. Manufacturers can cater to niche markets and respond swiftly to changing demands.

Digital Twin Technologies:

The integration of digital twin technologies is poised to further enhance Flexible Manufacturing Cell Design. Digital twins create virtual replicas of physical systems, enabling real-time monitoring, analysis, and optimization of manufacturing processes.

Conclusion: Paving the Way for Industry 4.0

In conclusion, Flexible Manufacturing Cell Design is paving the way for the future of manufacturing. Embracing adaptability and automation, these cells position industries to thrive in an era of dynamic market demands. As technology continues to evolve, the synergy between flexibility, automation, and efficiency will define the success of manufacturing operations in the years to come.