Unleashing Potential: The Impact of Data Analytics in Industry 4.0

In the era of Industry 4.0, the integration of data analytics is revolutionizing the manufacturing landscape. This transformative technology empowers industries to extract meaningful insights from vast datasets, driving informed decision-making, optimizing processes, and ushering in a new era of efficiency.

1. Foundations of Industry 4.0

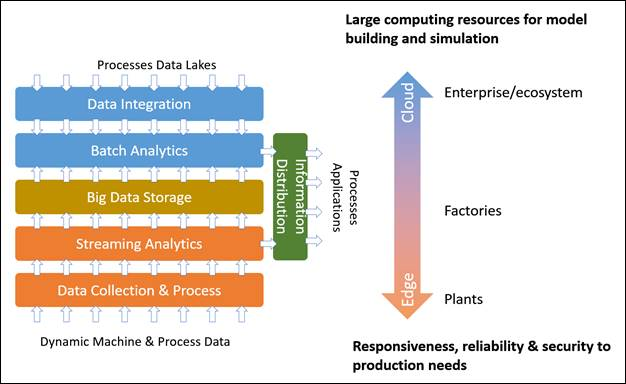

At the core of Industry 4.0 is the fusion of digital technologies with traditional manufacturing processes. This fourth industrial revolution embraces interconnected systems, IoT devices, and automation. Data analytics becomes the linchpin, turning raw data into actionable intelligence and catalyzing the evolution of smart factories.

2. Unlocking Insights with Advanced Analytics

Industry 4.0 data analytics goes beyond basic number crunching. Advanced analytics, including machine learning and artificial intelligence, play a pivotal role in uncovering patterns, trends, and correlations within datasets. This capability empowers manufacturers to gain deeper insights into their operations and make informed decisions based on data-driven predictions.

3. Predictive Maintenance for Operational Excellence

One of the significant applications of data analytics in Industry 4.0 is predictive maintenance. By analyzing historical and real-time data from machinery and equipment, predictive algorithms can forecast potential failures. This proactive approach minimizes downtime, extends the lifespan of equipment, and enhances overall operational efficiency.

4. Optimizing Production Processes

Data analytics enables manufacturers to optimize production processes in real-time. From demand forecasting to production scheduling, analytics tools leverage data from various sources to ensure that manufacturing processes align with market demands. This agility enhances efficiency, reduces waste, and allows for quick adaptation to changing conditions.

5. Enhancing Quality Control with Data Insights

Industry 4.0 data analytics is a game-changer for quality control. Advanced analytics tools, coupled with sensors and IoT devices, enable real-time monitoring of production processes. Any deviations from quality standards trigger immediate alerts, allowing for corrective actions and ensuring that only high-quality products reach the market.

6. Supply Chain Visibility and Resilience

In the interconnected world of Industry 4.0, data analytics extends its influence to the entire supply chain. Manufacturers gain unprecedented visibility into the movement of raw materials, production status, and distribution networks. This transparency enhances supply chain resilience, reduces lead times, and facilitates more strategic decision-making.

7. Personalized Manufacturing through Data Insights

Industry 4.0 facilitates a shift towards personalized manufacturing, and data analytics is the driving force behind customization. By analyzing customer preferences and market trends, manufacturers can tailor products to individual needs. This level of customization not only meets consumer expectations but also opens new avenues for innovation and market growth.

8. Cybersecurity in the Age of Industry 4.0

As data becomes more integral to manufacturing operations, cybersecurity becomes a paramount concern. Industry 4.0 data analytics includes robust cybersecurity measures to protect sensitive information. Encryption, secure access controls, and continuous monitoring are essential components in safeguarding the integrity of data in the connected manufacturing ecosystem.

9. Human-Machine Collaboration for Efficiency

Data analytics in Industry 4.0 isn’t about replacing human involvement but enhancing it. Human-machine collaboration becomes more seamless as data insights inform decision-making processes. Workers can leverage data-driven recommendations to optimize workflows, troubleshoot issues, and contribute to a more efficient and responsive manufacturing environment.

10. Navigating the Future with Industry 4.0 Data Analytics

As Industry 4.0 continues to evolve, the role of data analytics will only become more prominent. Manufacturers embracing this technology are positioned to thrive in an era of digital transformation. To explore the transformative impact of Industry 4.0 data analytics, visit Industry 4.0 Data Analytics. Dive into the innovations shaping the future of manufacturing through data-driven insights.