Advancing Precision: Navigating Trends in Automated Inspection Systems

Automated Inspection Systems have become integral to quality control and efficiency across various industries. As technology continues to advance, the trends in these systems are shaping the landscape of inspection processes, offering enhanced capabilities, precision, and adaptability.

*1. Introduction to Automated Inspection Systems

Automated Inspection Systems are a critical component of modern manufacturing, ensuring products meet stringent quality standards. These systems leverage advanced technologies such as machine vision, robotics, and artificial intelligence to perform intricate inspections with speed and accuracy.

*2. Integration of Artificial Intelligence (AI)

One prominent trend in automated inspection systems is the increasing integration of artificial intelligence. AI algorithms enhance the capabilities of these systems by enabling them to learn from data, recognize patterns, and adapt to variations in manufacturing processes. This results in improved accuracy and the ability to handle complex inspection tasks.

*3. Machine Learning for Adaptive Inspection

Machine learning, a subset of AI, is playing a pivotal role in making automated inspection systems more adaptive. These systems can now learn from real-time data, continuously improving their performance and adapting to variations in product specifications. This adaptability enhances the flexibility of automated inspection in dynamic manufacturing environments.

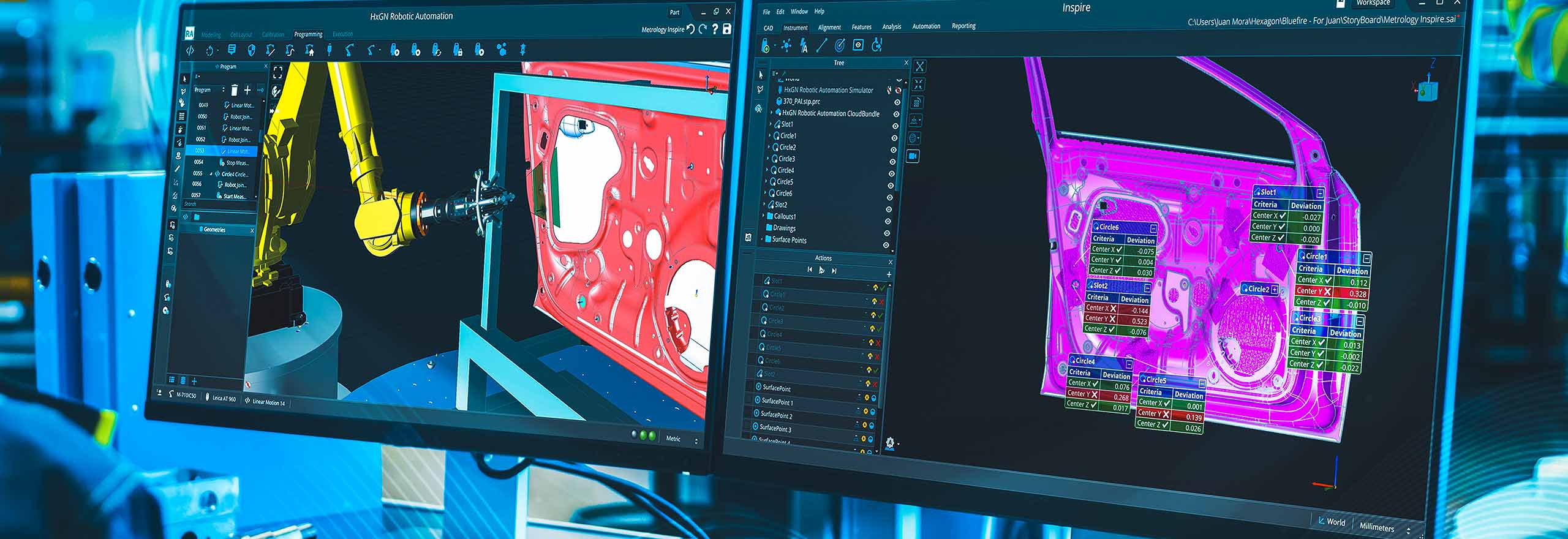

*4. Robotics for Versatile Inspection

The incorporation of robotics into automated inspection systems adds a layer of versatility. Robotic arms equipped with sensors and cameras can navigate complex surfaces, inspecting products from multiple angles. This trend in robotics enhances the range of products that automated inspection systems can effectively evaluate.

*5. 3D Vision Technology for Depth Perception

Traditional inspection methods often rely on 2D vision, limiting their ability to assess the depth of surfaces and features. The integration of 3D vision technology in automated inspection systems provides depth perception, allowing for more comprehensive and accurate inspections. This is particularly beneficial for complex components with intricate geometries.

*6. Real-Time Inspection Data Analytics

The trend towards real-time data analytics is transforming how inspection results are processed and utilized. Automated inspection systems now generate and analyze data instantaneously, providing actionable insights on the production line. This real-time capability allows for prompt adjustments and ensures that defects are identified and addressed promptly.

*7. IoT Connectivity for Remote Monitoring

The Internet of Things (IoT) is influencing automated inspection systems by enabling remote monitoring and control. Manufacturers can now monitor inspection processes and receive real-time updates on their smartphones or other devices. This connectivity enhances efficiency and facilitates timely decision-making, even from a distance.

*8. Augmented Reality (AR) in Inspection Processes

The incorporation of augmented reality in automated inspection is gaining traction. AR overlays digital information onto the physical world, providing operators with real-time guidance during inspections. This trend enhances operator efficiency, reduces human errors, and contributes to a more intuitive inspection process.

*9. Increased Use of Hyperspectral Imaging

Hyperspectral imaging is emerging as a powerful tool in automated inspection systems. This technology captures a broad spectrum of wavelengths, allowing for detailed analysis of materials and surface properties. The increased use of hyperspectral imaging enhances the capabilities of automated inspection, particularly in industries requiring precise material identification.

*10. Environmental and Sustainability Considerations

An emerging trend in automated inspection systems revolves around environmental and sustainability considerations. Manufacturers are increasingly focused on incorporating inspection processes that minimize waste and energy consumption. This shift aligns with broader industry efforts to adopt eco-friendly practices and reduce the environmental impact of manufacturing operations.

To explore the latest trends in Automated Inspection Systems, visit Automated Inspection Systems Trends. Dive into the innovations shaping the future of quality control and precision inspection in manufacturing processes.