Revolutionizing Production with Flexible Manufacturing Cell Design

Flexible manufacturing cell design is at the forefront of revolutionizing production processes across industries. This innovative approach is transforming traditional manufacturing setups, offering unparalleled adaptability, efficiency, and versatility. Let’s delve into the key aspects that make flexible manufacturing cell design a game-changer in today’s dynamic industrial landscape.

Adapting to Changing Production Demands

The cornerstone of flexible manufacturing cell design lies in its ability to adapt to changing production demands. Unlike rigid, specialized setups, flexible manufacturing cells can be easily reconfigured to accommodate different product lines or variations. This adaptability ensures that manufacturers can swiftly respond to market changes and customer preferences without significant disruptions.

Modular Components for Seamless Integration

Central to the concept of flexible manufacturing cells is the use of modular components. Each component serves a specific function, and these modules can be easily integrated or rearranged to create a customized production line. This modularity not only simplifies the initial setup but also facilitates future modifications or expansions, providing manufacturers with long-term flexibility.

Improved Efficiency and Reduced Downtime

The flexibility inherent in this manufacturing approach leads to improved efficiency and reduced downtime. With the ability to reconfigure cells quickly, manufacturers can optimize production flows, minimize changeover times, and enhance overall equipment utilization. This results in a streamlined production process that maximizes output while minimizing idle time.

Enhanced Automation and Robotics Integration

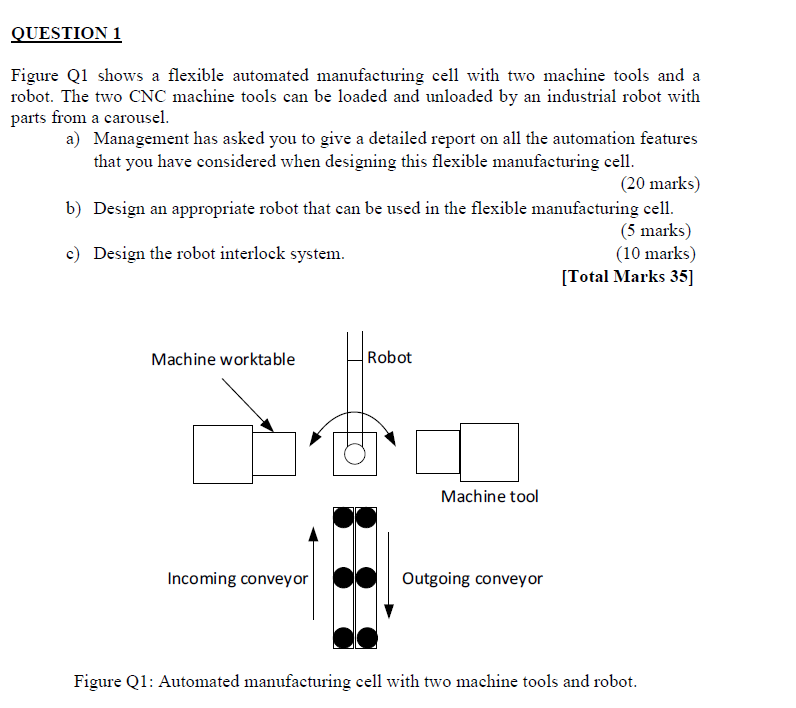

Flexible manufacturing cell design aligns seamlessly with the integration of automation and robotics. These cells can be equipped with robotic systems to handle tasks such as material handling, assembly, and quality control. The synergy between flexible design and automation contributes to increased precision, speed, and consistency in manufacturing operations.

Scalability for Future Growth

Scalability is a critical factor in today’s dynamic business environment, and flexible manufacturing cells excel in this regard. Manufacturers can scale their operations easily by adding or adjusting cells based on evolving production needs. This scalability ensures that businesses are well-positioned for growth without the need for substantial retooling or capital investments.

Worker Empowerment and Skill Development

While automation plays a significant role in flexible manufacturing cell design, human operators remain essential. This approach empowers workers by involving them in the operation, monitoring, and maintenance of the flexible cells. The adaptability of these cells also encourages ongoing skill development, ensuring that the workforce remains versatile and capable of handling diverse tasks.

Cost-Efficiency and Resource Optimization

Flexibility in manufacturing cells translates into cost-efficiency and resource optimization. Manufacturers can allocate resources more effectively, reduce waste, and optimize energy consumption. The modular nature of the cells also allows for targeted investments in specific components, optimizing the use of financial resources.

Meeting Customization Demands

In an era where customization is increasingly valued, flexible manufacturing cell design is a key enabler. The ability to quickly reconfigure cells allows manufacturers to cater to custom orders, varying specifications, and changing customer preferences. This agility is particularly crucial in industries where product customization is a competitive advantage.

Environmental Sustainability in Manufacturing

The efficiency and resource optimization inherent in flexible manufacturing cell design contribute to environmental sustainability. By minimizing waste, reducing energy consumption, and optimizing production processes, manufacturers adopting this approach play a vital role in creating a more sustainable and eco-friendly manufacturing landscape.

To explore the transformative potential of flexible manufacturing cell design, visit paydayukloan.com. Discover how this innovative approach can reshape your production processes, providing adaptability, efficiency, and sustainability in today’s ever-evolving industrial landscape.