Transformative Impact of 3D Printing in Aerospace

In the realm of aerospace manufacturing, 3D printing has emerged as a revolutionary force, transforming traditional processes and opening new frontiers. Explore the profound impact of 3D printing advancements in the aerospace industry, shaping the way aircraft components are designed, produced, and maintained.

Design Freedom and Complex Geometries

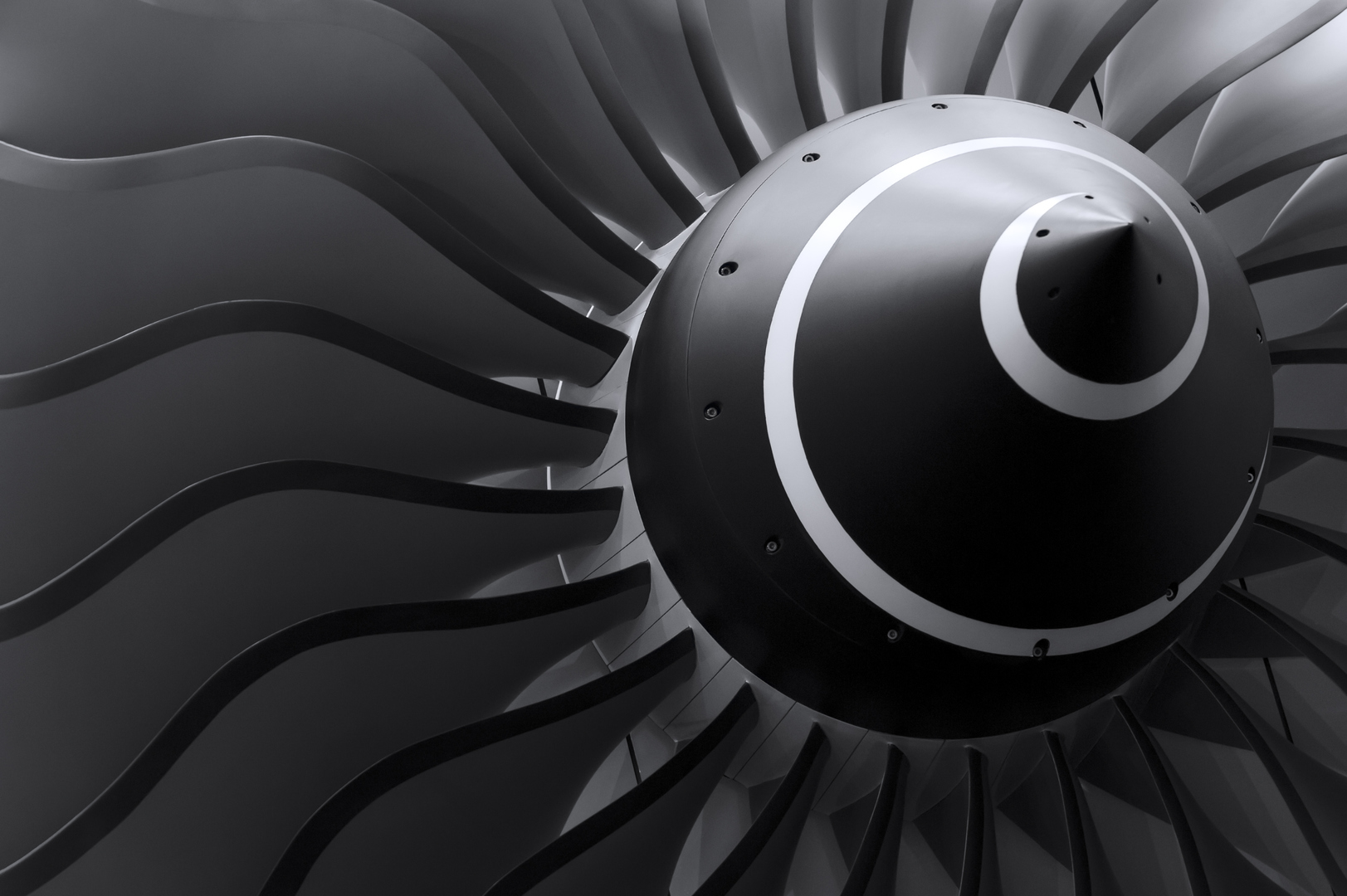

One of the key advantages of 3D printing in aerospace manufacturing is the unparalleled design freedom it offers. Traditional manufacturing methods often face limitations in producing complex geometries, but 3D printing allows for intricate and sophisticated designs. This capability is particularly beneficial in crafting components that are both lightweight and structurally robust.

Lightweight Structures for Enhanced Efficiency

Aerospace engineering places a premium on weight reduction for improved fuel efficiency and overall performance. 3D printing enables the creation of lightweight structures without compromising strength. By using advanced materials and intricate lattice structures, aerospace components can be designed to achieve optimal strength-to-weight ratios, contributing to fuel savings and increased payload capacity.

Rapid Prototyping and Iterative Development

The iterative nature of aerospace design often demands rapid prototyping and frequent iterations. 3D printing facilitates this process by allowing for quick and cost-effective production of prototypes. Engineers can swiftly test and refine designs, accelerating the development cycle and ensuring that final components meet the highest standards of performance and safety.

Customization and Tailored Solutions

Every aircraft may have unique requirements, and 3D printing enables the customization of components to suit specific needs. Whether it’s crafting a specialized bracket or creating a personalized interior component, 3D printing empowers aerospace manufacturers to tailor solutions with precision. This level of customization enhances efficiency and ensures optimal integration within the aircraft.

Improved Supply Chain Efficiency

Traditional aerospace manufacturing often involves complex supply chains with numerous suppliers for different components. 3D printing has the potential to simplify supply chains by producing certain parts on-demand. This not only reduces the reliance on extensive inventories but also streamlines logistics, leading to cost savings and increased overall efficiency in the aerospace supply chain.

Enhanced Maintenance and Repairs

Beyond initial production, 3D printing plays a crucial role in aerospace maintenance and repairs. The ability to recreate intricate components on-site, often referred to as “on-demand manufacturing,” reduces downtime for repairs. Airlines and maintenance teams can swiftly replace damaged parts with 3D-printed replicas, minimizing aircraft grounding and enhancing operational continuity.

Materials Innovation and Performance

Advancements in 3D printing materials contribute significantly to aerospace innovation. Specialized materials with high heat resistance, durability, and performance characteristics are developed for specific aerospace applications. This constant evolution of materials allows for the creation of components that meet or exceed the stringent requirements of aerospace standards.

Regulatory Challenges and Certification

As 3D printing gains prominence in aerospace, regulatory challenges and certification processes become critical considerations. Ensuring that 3D-printed components meet stringent safety and quality standards is paramount. The aerospace industry collaborates with regulatory bodies to establish guidelines and certifications for the use of 3D-printed parts in critical aircraft systems.

Future Prospects and Emerging Technologies

The journey of 3D printing in aerospace manufacturing is dynamic, with ongoing research and development pushing the boundaries of what is possible. Emerging technologies, such as metal 3D printing and advancements in multi-material printing, hold promise for further revolutionizing the industry. These developments pave the way for enhanced performance, increased sustainability, and broader applications in aerospace.

Exploring the Potential at the Forefront

To delve into the forefront of 3D printing advancements in aerospace manufacturing, visit paydayukloan.com. Discover how these innovative technologies are reshaping the aerospace industry, driving efficiency, sustainability, and pushing the boundaries of what is achievable in aircraft design and production.